Preventative maintenance is a crucial aspect of keeping any system or equipment running smoothly and efficiently. Whether it’s your car, your home appliances, or your computer, regular maintenance can help you avoid costly repairs and unexpected breakdowns. By following a preventative maintenance checklist, you can stay on top of routine tasks and ensure that everything is in good working order.

What is Preventative Maintenance?

Preventative maintenance involves performing regular inspections, cleanings, and adjustments on equipment to prevent potential issues from arising. It is a proactive approach to maintenance that focuses on preventing problems before they occur, rather than waiting for something to break down before fixing it. By following a preventative maintenance checklist, you can ensure that all necessary tasks are completed on time and that your equipment remains in top condition.

The Purpose of Preventative Maintenance

Image Source: scribdassets.com

The main purpose of preventative maintenance is to reduce the likelihood of equipment failure and minimize downtime. By performing regular maintenance tasks, you can identify and address potential issues before they escalate into major problems. This can help you avoid costly repairs, improve the lifespan of your equipment, and maintain its efficiency and performance over time. Preventative maintenance also helps to ensure the safety of users by keeping equipment in safe working condition.

Why Preventative Maintenance is Important

Preventative maintenance is important for several reasons. First and foremost, it can save you money in the long run by preventing costly repairs and replacements. By identifying and addressing issues early on, you can avoid more extensive damage and keep your equipment running smoothly. Additionally, preventative maintenance can help you avoid unexpected breakdowns, which can disrupt your daily routine and cause inconvenience. Regular maintenance also helps to maintain the value of your assets and ensures that they continue to perform at their best.

How to Create a Preventative Maintenance Checklist

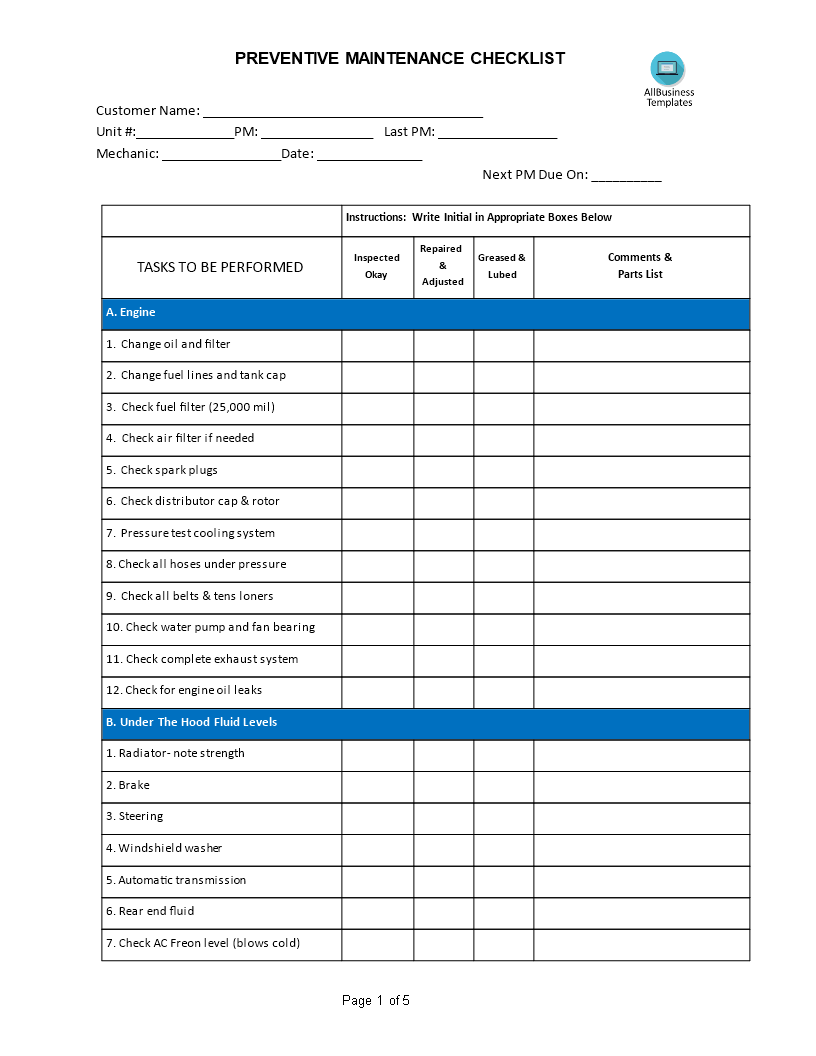

Image Source: pinimg.com

Creating a preventative maintenance checklist is essential for staying organized and ensuring that all necessary tasks are completed on time. Start by identifying all the equipment and systems that require maintenance, including their specific maintenance requirements and schedules. You can use manufacturer guidelines, equipment manuals, and industry best practices to create a comprehensive checklist for each item. Be sure to include tasks such as inspections, lubrication, filter changes, calibrations, and any other maintenance activities specific to each piece of equipment.

1. Identify Equipment

Before creating a preventative maintenance checklist, make a list of all the equipment and systems that require maintenance. This can include vehicles, household appliances, HVAC systems, and more. Be sure to include all relevant information such as make, model, serial number, and maintenance history.

2. Determine Maintenance Requirements

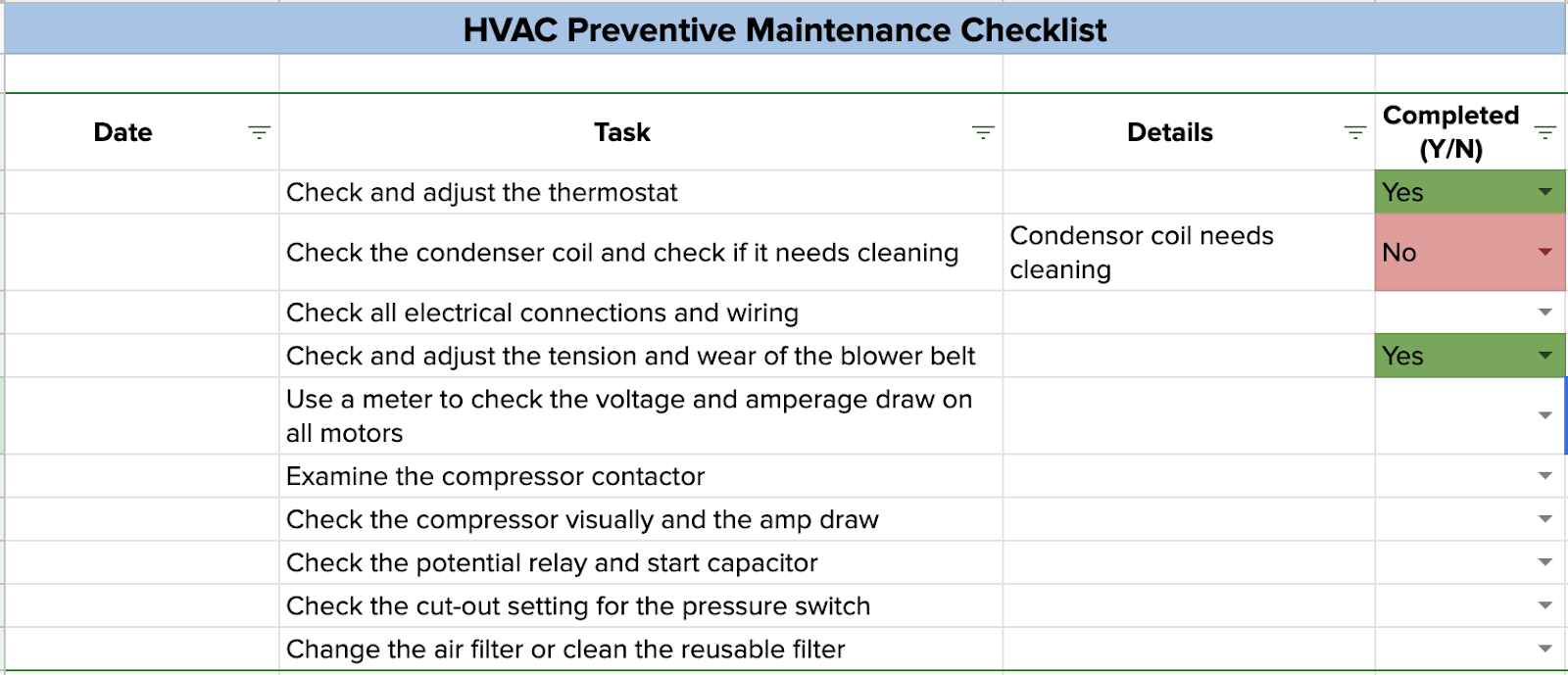

Image Source: propertymeld.com

Once you have identified the equipment, determine the specific maintenance requirements for each item. This may include tasks such as oil changes, filter replacements, belt adjustments, and visual inspections. Refer to manufacturer guidelines and equipment manuals for detailed maintenance instructions.

3. Create a Schedule

Establish a regular maintenance schedule for each item on your checklist. This can be based on time intervals (e.g., monthly, quarterly, annually) or usage intervals (e.g., every 5,000 miles, every 100 hours of operation). Be sure to allocate enough time for each maintenance task and schedule them in advance to ensure they are completed on time.

4. Assign Responsibilities

Image Source: scribdassets.com

Assign responsibilities for each maintenance task to specific individuals or departments. Clearly define who is responsible for performing each task, as well as who is responsible for overseeing the overall maintenance program. This helps ensure accountability and prevents tasks from falling through the cracks.

5. Document Maintenance Activities

Keep detailed records of all maintenance activities, including dates, tasks performed, and any issues identified. This documentation can help track the maintenance history of each item, identify trends or recurring problems, and provide a reference for future maintenance needs. Consider using a digital maintenance management system to streamline documentation and record-keeping.

6. Monitor and Evaluate Performance

Image Source: datocms-assets.com

Regularly monitor and evaluate the performance of your preventative maintenance program. Look for areas of improvement, such as tasks that may need to be adjusted or equipment that may require more frequent maintenance. Use performance data to make informed decisions and continuously optimize your maintenance checklist for better results.

7. Adapt to Changing Needs

As equipment ages or usage patterns change, be prepared to adapt your preventative maintenance checklist to meet changing needs. Regularly review and update the checklist to ensure that it remains relevant and effective. Consider feedback from maintenance technicians, equipment operators, and other stakeholders to make informed adjustments as needed.

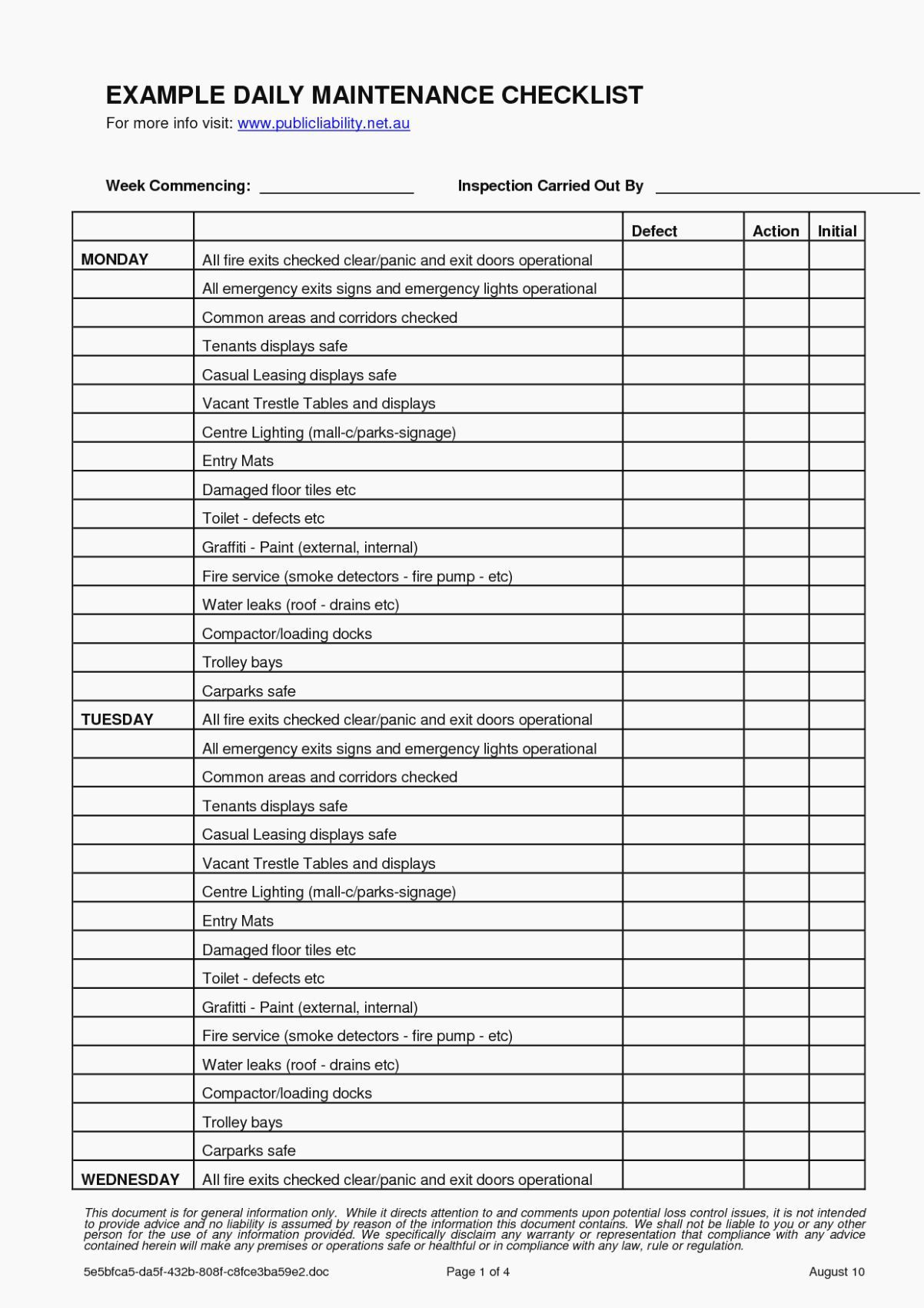

8. Stay Compliant with Regulations

Image Source: firmresponse.com

Ensure that your preventative maintenance checklist complies with relevant regulations and safety standards. This may include requirements set by regulatory agencies, industry associations, or equipment manufacturers. Stay informed about any updates or changes to regulations that may impact your maintenance practices and adjust your checklist accordingly.

Tips for Successful Preventative Maintenance

Preventative maintenance can be a key factor in the longevity and performance of your equipment. Here are some tips to help ensure the success of your maintenance program:

Image Source: googleusercontent.com

Regular Inspections: Perform regular inspections to identify potential issues before they escalate.

Follow Manufacturer Guidelines: Adhere to manufacturer guidelines for maintenance tasks and schedules.

Train Personnel: Provide training for maintenance technicians and equipment operators to ensure tasks are performed correctly.

Use Technology: Consider using maintenance management software or tools to streamline maintenance activities and documentation.

Prioritize Safety: Always prioritize safety when performing maintenance tasks and follow proper safety protocols.

Schedule Downtime: Plan maintenance tasks during scheduled downtime to minimize disruptions to operations.

In conclusion,

Image Source: pinimg.com

A preventative maintenance checklist is a valuable tool for keeping your equipment in top condition and avoiding costly repairs. By following a comprehensive checklist and staying organized, you can ensure that all necessary maintenance tasks are completed on time and that your equipment remains in good working order. Remember to regularly monitor and evaluate your maintenance program, adapt to changing needs, and prioritize safety to ensure the success of your preventative maintenance efforts.

Blank Preventive Maintenance Checklist in Word

Image Source: generalblue.com

Image Source: sitemate.com