Preventive maintenance is a crucial aspect of keeping equipment, machinery, and systems in optimal working condition. By regularly inspecting, servicing, and repairing items before they fail, you can prevent costly downtime and extend the lifespan of your assets. A preventive maintenance checklist is a tool used to ensure that all necessary maintenance tasks are completed on schedule. This checklist typically includes a list of equipment, inspection points, tasks to be completed, and the frequency at which they should be done.

What is a Preventive Maintenance Checklist?

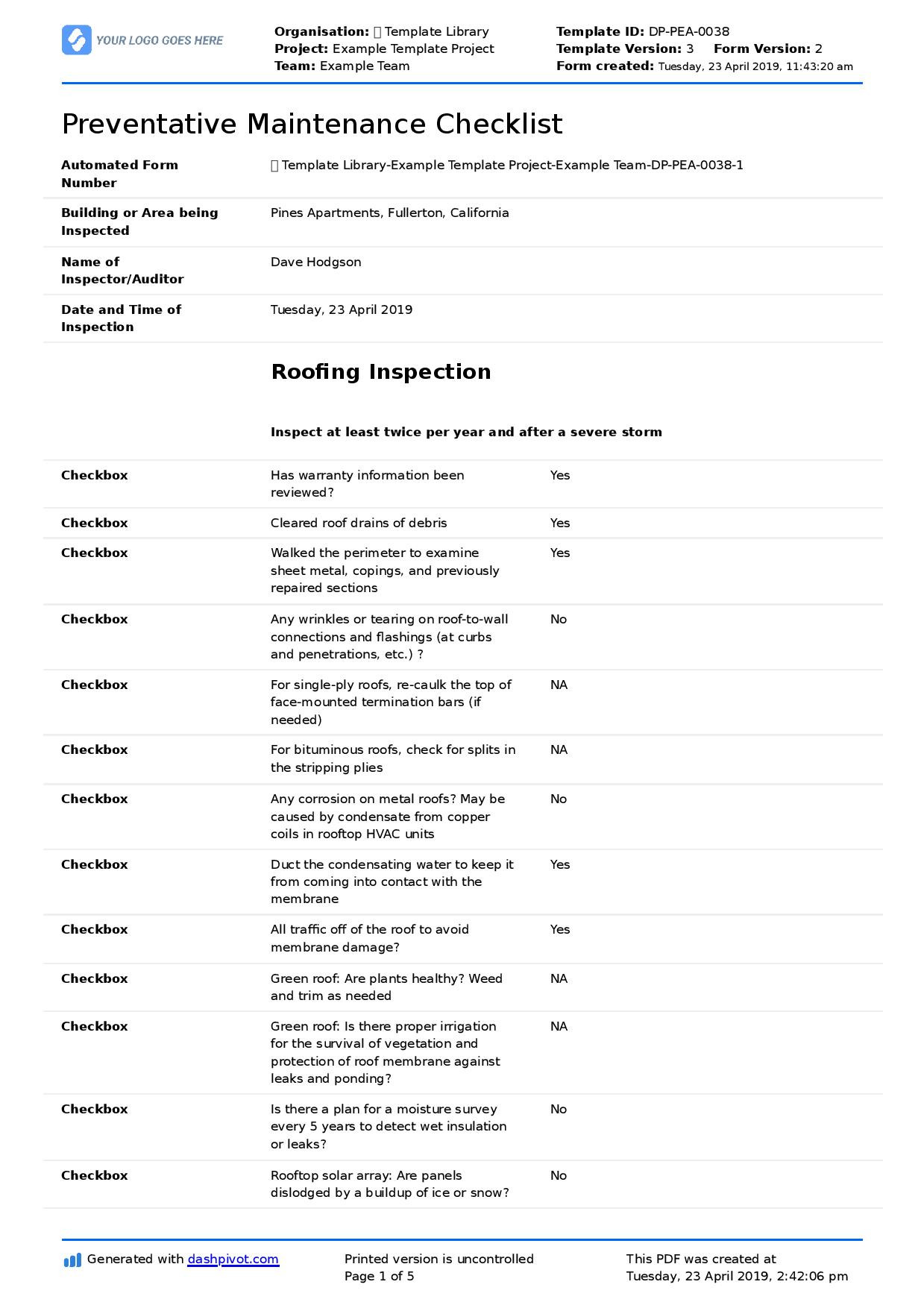

A preventive maintenance checklist is a document that outlines the maintenance tasks that need to be performed on equipment or systems to prevent breakdowns and ensure smooth operation. It serves as a guide for maintenance technicians and facility managers to ensure that all necessary tasks are completed on time. The checklist can include items such as inspections, lubrication, cleaning, calibration, and replacement of parts.

Image Source: scribdassets.com

Creating a preventive maintenance checklist involves identifying all the equipment and systems that require maintenance, determining the tasks that need to be performed, setting a schedule for when each task should be completed, and assigning responsibilities to specific individuals. By following a checklist, organizations can stay on top of maintenance tasks and avoid unexpected breakdowns.

The Purpose of a Preventive Maintenance Checklist

The main purpose of a preventive maintenance checklist is to prevent equipment failures and downtime by ensuring that regular maintenance tasks are performed on schedule. By conducting routine maintenance, organizations can identify and address minor issues before they escalate into major problems. This proactive approach helps to extend the lifespan of equipment, improve efficiency, and reduce repair costs.

Image Source: pinimg.com

Another key purpose of a preventive maintenance checklist is to comply with regulatory requirements and industry standards. Many industries have specific regulations that require equipment to be inspected and maintained regularly to ensure safety and compliance. By following a preventive maintenance checklist, organizations can demonstrate that they are taking the necessary steps to maintain their equipment in good working condition.

Why Use a Preventive Maintenance Checklist?

Using a preventive maintenance checklist offers several benefits for organizations. Some of the key reasons why a checklist is essential include:

Image Source: datocms-assets.com

1. Preventing breakdowns: By conducting regular maintenance tasks, organizations can identify and address issues before they lead to equipment failures and costly downtime.

2. Increasing equipment lifespan: Regular maintenance helps to keep equipment in optimal condition, extending its lifespan and reducing the need for premature replacement.

3. Improving efficiency: Well-maintained equipment operates more efficiently, leading to increased productivity and reduced energy consumption.

4. Reducing repair costs: Addressing minor issues through regular maintenance can prevent them from escalating into major problems that require costly repairs.

5. Ensuring safety and compliance: Regular maintenance helps to ensure that equipment meets safety standards and regulatory requirements, reducing the risk of accidents and non-compliance penalties.

Steps to Building a Preventive Maintenance Checklist (With Free

Image Source: googleusercontent.com

Image Source: firmresponse.com

Image Source: generalblue.com

Image Source: sitemate.com